Imagine an industry transporting goods worth over $14 trillion, controlling 80% of global trade by volume, 70% by value, and being the cheapest mode of transportation for goods worldwide- that’s the Shipping Industry for you. It’s a dynamic space where economic forces, geopolitics, and regulations collide. Even small changes in freight rates can ripple through the economy, impacting commodity prices and inflation.

In this article, we'll take a deep dive into how the shipping industry works

Picture this: It’s early August, and Walmart, one of the largest retailers in the U.S., is anticipating a major surge in demand for home textiles as the holiday season approaches. Walmart knows that come Thanksgiving, millions of Americans will be looking for new blankets, bedsheets, towels, and other bedding and bath textiles to freshen up their homes. To prepare, Walmart’s procurement team places an enormous order with one of its trusted suppliers in India – Raymond Ltd. The largest integrated textile company in the world, Raymond specializes in high-quality home goods and has been supplying bedding and bath products to global retailers for years.

Step 1: The Order is Placed, and Manufacturing Begins

The Walmart team sends over detailed specifications and the anticipated volumes of each item: blankets, blankets, bedsheets, pillow covers, towels, and bathrobes. Raymond’s manufacturing facility in Vapi, Gujarat springs into action. Production schedules are drawn up, raw materials are sourced, and the assembly lines are set to deliver these products in record time.

However, Raymond doesn’t have an in-house logistics department. So for assistance with the custom clearance and transportation of the finished products across oceans, it hires a freight forwarding company.

What is a Freight Forwarding?

Freight forwarding is the process of moving imports and exports through the supply chain.

Freight Forwarders (also known as Forwarding Agents) work with multiple clients simultaneously, booking cargo space in bulk across ships, planes, trains, and trucks based on product requirements. Their strong relationships and substantial bargaining power with shipping lines, airlines, trucking companies, and rail operators enables them to negotiate optimal routes and rates for their clients.

They handle all necessary paperwork, including bills of lading and customs declarations, ensuring compliance with legal requirements to prevent delays. Additionally, they arrange cargo insurance to protect shipments. The client determines the extent of the forwarder's involvement in managing their goods' journey.

Some major freight forwarding companies include:

UPS (USA)

FedEx (USA)

DHL Supply Chain & Global Forwarding (Germany)

Kuehne + Nagel (Switzerland)

Blue Dart Express (India)

Step 2: Submitting Documents for Customs Clearance

So with Walmart’s order specifications in hand, Raymond contacts UPS, a global logistics leader. As the freight forwarder, UPS will oversee the entire journey of these products, from the manufacturing plant in Gujarat to Walmart’s distribution centers in the U.S. UPS will also ensure all required documentation for customs clearance is meticulously prepared to meet international shipping standards.

UPS works with Raymond to prepare the necessary documentation, like:

Commercial Invoice: Details of the products, quantities, and the transaction value.

Packing List: Listing of all items in each package for easy inspection.

Certificate of Origin: Proof that the goods are made in India.

Shipping Bill: Required for customs clearance, containing details about the goods and their intended export.

Bill of Lading: A contract between the shipper and the carrier, issued once the cargo is loaded onto the vessel.

All these documents are digitally submitted to the Indian Customs Electronic Gateway (ICEGATE) portal. ICEGATE streamlines customs procedures, allowing all information to be filed electronically. This setup is crucial, as it eliminates paper-based delays and expedites the export process for Raymond’s products.

What’s The Role Of Customs Department?

The customs department plays a crucial role in international trade by acting as the gatekeeper for goods entering and leaving a country. Their primary responsibilities include collecting customs duties and taxes, ensuring that all imported and exported goods comply with national regulations, verifying documentation and ensuring that all goods meet the necessary standards and inspecting shipments to prevent illegal activities such as smuggling. By overseeing these processes, customs helps facilitate smooth trade operations while also protecting the economy and public safety.

Step 4: Booking Space In A Shipping Line

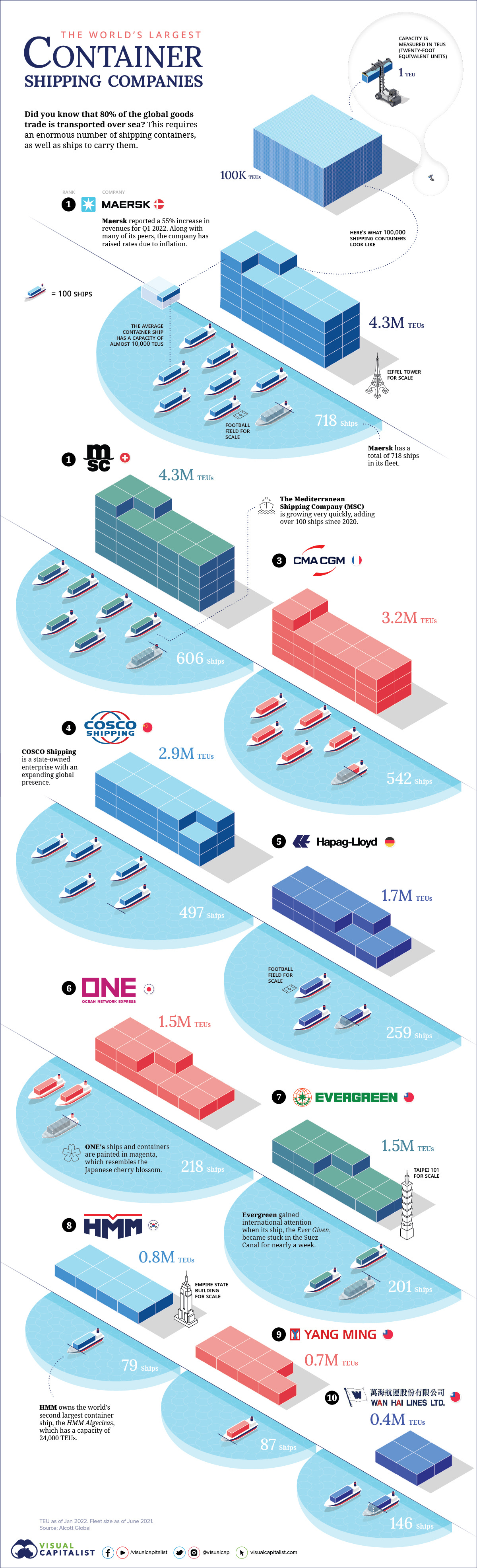

With the documents underway, UPS now negotiates with various shipping lines to find the best route and rates for this bulk textile shipment. Shipping giants like Maersk or Mediterranean Shipping Company (MSC) are prominent players in this space.

sea freight rates vary depending on various factors, including:

Route - Longer distances and more complex routes generally result in higher rates.

Transportation type - LCL (Less than Container Load) type of transportation is chosen if the exporter can’t fill an entire shipping container with its goods. This option is cheaper than FCL (Full Container Load) transportation.

Characteristics of the cargo - type, amount, weight, and dimensions

Shipment’s insurance - High value goods that are subject to higher insurance will increase the shipping costs

Time of year - The holiday shopping season which normally spans between August to October, sees an increase in demand for container shipments, resulting in increased rates. On the other hand, during off-peak seasons, from March to June, prices drop due to less demand.

UPS reviews schedules, prices, and the reliability of each shipping line’s service before finalizing the booking. Once it chooses Maersk as the carrier, UPS books space on a vessel that will leave the the Mundra Port in Gujarat, managed by Adani Ports and Special Economic Zone (APSEZ), India’s largest private port operator. Maersk confirms the booking with a booking number and assigns a container identification number, indicating the reserved space for Raymond’s textiles on their vessel.

These details will later help track the cargo throughout its journey.

Step 5: Transportation to the Port

Raymond’s facility completes production right on schedule, and the blankets, bedsheets, and other textiles are packed, labeled, and loaded onto pallets. Each product is carefully packed to avoid any damage during the ocean journey. By this time, Let Export Order (LEO) has been issued by Indian Customs, indicating that the goods have cleared customs on the Indian side and are ready for export.

With the products packaged and ready to go, UPS arranges trucks to transport the goods from Raymond’s manufacturing facility to Mundra Port.

Step 6: Loading the Cargo

As the trucks arrive at Mundra, Adani Ports’ team handles the cargo’s entry and directs it to the designated container yard. UPS coordinates with the port operator and Maersk’s team, ensuring that the cargo is securely loaded into the container.

Then using large cranes and specialized technology, Adani Ports carefully loads the container onto the designated Maersk’s ship, double-checking the container identification against the booking number provided by Maersk. Each container is placed according to a precise loading plan that ensures balance and safety during the ship’s journey.

Step 7: Receiving the Bill of Lading

Once the cargo is securely loaded, Maersk issues the Bill of Lading (B/L), to UPS. This Bill of Lading acts as a receipt, confirming that the goods are safely onboard and ready to be shipped.

The Bill of Lading includes:

Booking Number and Container Number: Confirming the specific allocation of space for the shipment.

Port of Loading (POL) and Port of Discharge (POD): Mundra Port in India and, in this case, Los Angeles Port in the United States.

It also outlines the terms of shipment and serves as proof of the cargo’s ownership, which will later be required by Walmart to take possession of the shipment.

This document will be key for both Raymond and Walmart; it confirms that Maersk has taken possession of the goods and is now responsible for their transport.

Step 8: The Sea Voyage Begins

The ship sets off from Mundra Port, following a pre-defined route to the United States. Maersk’s vessel will make a series of stops at transshipment hubs along the way to unload and load other cargo, maximizing efficiency. During this journey, the textiles remain securely in their designated container as the vessel navigates through the Indian Ocean, around the Arabian Peninsula, across the Suez Canal, and finally, across the Atlantic Ocean. This journey will take several weeks, during which time Maersk’s vessel follows a tightly monitored route, navigating weather conditions, busy trade lanes, and port schedules.

Step 9: Preparing Import Documents

As the ship nears the Port of Los Angeles, Walmart’s import team begins preparing for its arrival. They work closely with UPS, who will also handle the import side of the customs process, saving Walmart the hassle of managing the paperwork itself, to ensure that all necessary import documentation is ready. These documents typically include:

Bill of Lading: Provided by Maersk as proof of shipment.

Certificate of Origin: A document that certifies the country of origin for certain products.

Insurance certificate: A document that provides proof of insurance coverage for the shipment, in case it is lost or damaged.

Letter of credit: A document shared by the importer's bank, stating that the importer will pay the exporter the specified sum to complete the transaction.

Bill of Entry (Customs Declaration): Submitted to U.S. Customs and Border Protection (CBP), detailing the contents and value of the shipment.

This proactive approach helps prevent any potential delays at the destination port.

Step 10: Arrival at the Destination Port and Customs Clearance

The Maersk vessel finally arrives at the Port of Los Angeles, one of the busiest ports in the United States. UPS, as the freight forwarder, steps in again to handle customs clearance for Walmart. They initiate the customs clearance process by submitting the Bill of Entry to U.S. Customs. This document provides a detailed account of the goods within each container, including descriptions, quantities, and total value.

The customs officers at the port verify the paperwork and may conduct a physical inspection to ensure the contents match the declaration. They also checks for any prohibited items or issues with the shipment. Once the inspection is complete, U.S. Customs calculates the duties, taxes, and fees owed, based on the shipment's value, type, and origin.

Once Walmart pays the required duties and fees, U.S. Customs issues clearance for the textiles, and the container is officially released and ready to leave the port.

With customs clearance granted, The container is unloaded from the ship. transferred to a truck, and transported to Walmart’s warehouse,

Step 11: Final Delivery to Walmart’s Distribution Center

With customs clearance granted, UPS arranges the final leg of the journey: transporting the goods from the Port of Los Angeles to one of Walmart’s distribution centers. This might involve trucking the containers across California or transferring them to rail for longer-distance distribution. Once at the distribution centers, the textiles are sorted and stored until they are needed by individual Walmart stores.

For instance, Walmart Distribution Center in Bentonville, Arkansas serves as a major hub for distributing goods throughout the central U.S., while Walmart Distribution Center in California is crucial for serving stores on the West Coast.

Types of Cargo Ships

As our cargo was textiles, it could be neatly packed into containers, transported on container ships. But not all cargo fits so conveniently into a container. Think of oversized machinery, liquid chemicals, or even bulk commodities like grains. Different types of goods require specialized ships to ensure safe transport across oceans. Let’s explore the common types of ships used to move different kinds of cargo.

Bulk Carrier Ships (or Dry Bulk Carrier)

When an exporter needs to ship loose materials that do not require any individual packaging like grains, iron ore, sand and coal, dry bulk carriers are used.

These ships are massive and sturdy, with large open holds designed to carry unpackaged bulk goods in huge quantities. These goods are dry, non-perishable goods non-hazardous or corrosive, & usually used as raw materials in various industries.

India exports tons of iron ore from companies like NMDC Ltd and Vedanta to steel manufacturers in markets like Japan, China, and South Korea. Dry bulk carriers are used for this because although Iron ore doesn’t require special packaging, but it’s very heavy and dense. A dry bulk carrier is able to handle this weight and safely transport iron ore over long distances.

Reefer Ships (or Refrigerated Ships)

To transport perishable goods like temperature-sensitive goods like fruits, vegetables, pharmaceuticals, and seafood, reefer ships are used. These ships are equipped with advanced refrigeration systems and insulated storage, perfect for goods that require controlled temperatures, ensuring perishable items remain fresh.

Avanti Feeds Ltd, a prominent seafood exporter, ships frozen shrimp to the U.S. and Europe. Using reefer ships, they ensure the shrimp stays frozen throughout the journey.

Tanker Ships (or Liquid Bulk Carriers)

Tanker Ships are specialized for transporting liquid cargo, such as crude oil, chemicals, and liquefied natural gas (LNG). They come in various types—oil tankers, chemical tankers, and LNG carriers—each designed to handle a specific type of liquid cargo. Tankers are built with compartments to prevent liquids from shifting, which can destabilize the ship. Advanced safety features also minimize the risk of leaks or spills.

Reliance Industries Limited (RIL) is one of India’s biggest exporters of refined petroleum products like diesel, petrol, and jet fuel from Jamnagar Port—home to the world’s largest refinery complex. Reliance’s tankers deliver refined oil products to markets in Southeast Asia, the Middle East, and Africa. Major destination ports include Fujairah (UAE) and Singapore, both critical hubs for petroleum trade.

RoRo Ships (or Roll-On/Roll-Off Ships)

RoRo ships are designed to transport vehicles and machinery, such as cars, trucks, and heavy construction equipment. Vehicles are driven directly onto the ship and parked in designated areas. RoRo ships have built-in ramps and secure parking decks, allowing vehicles to roll on and roll off smoothly, saving time and reducing handling risks. Maruti Suzuki, one of India’s largest automobile manufacturers, exports cars to Africa and Latin America. They use RoRo ships to transport vehicles via Mumbai Port and Ennore Port, both equipped for automotive exports.

Container Ships

Container ships carry goods in standardized containers, making them ideal for consumer goods, electronics, and textiles. Containers simplify loading and unloading, improving efficiency across the entire supply chain.

Before containers, goods were packed in barrels, sacks, or boxes and loaded individually onto ships. This process was slow, labor-intensive, and prone to damage and theft.

In 1956, Malcolm McLean, an American trucking entrepreneur, invented the standardized shipping container, a standardized metal box that could fit on both trucks and ships. Containers reduced loading times, costs, and made it possible to transport goods securely across various modes of transportation.

This innovation sped up the process, cut costs, and spurred global trade.

As we discussed earlier, Raymond used a container ship to transport its textile shipment to America.

General Cargo Ships

General cargo ships are the most flexible type, carrying a variety of cargo that doesn't fit neatly into containers or bulk shipments. They’re ideal for items like machinery, construction equipment, and other large or irregularly shaped goods. These ships have versatile holds that can be adjusted depending on the cargo. Some are even geared, i.e. equipped with their own cranes to manage loading and unloading, which is especially helpful in smaller ports without advanced infrastructure. Their flexibility makes them ideal for mixed loads. General cargo ships often operate on tramp services, meaning they don’t follow fixed routes or schedules but go where the cargo needs them—like taxis of the ocean!

Larsen & Toubro (L&T), a major engineering and construction company, exports large machinery and industrial parts to the Middle East and Africa. They use general cargo ships to handle oversized equipment from Mumbai Port and Chennai Port. L&T’s machinery heads to construction and industrial sites in countries like Saudi Arabia and Nigeria, where it’s used in infrastructure projects.

The Geopolitical Chessboard

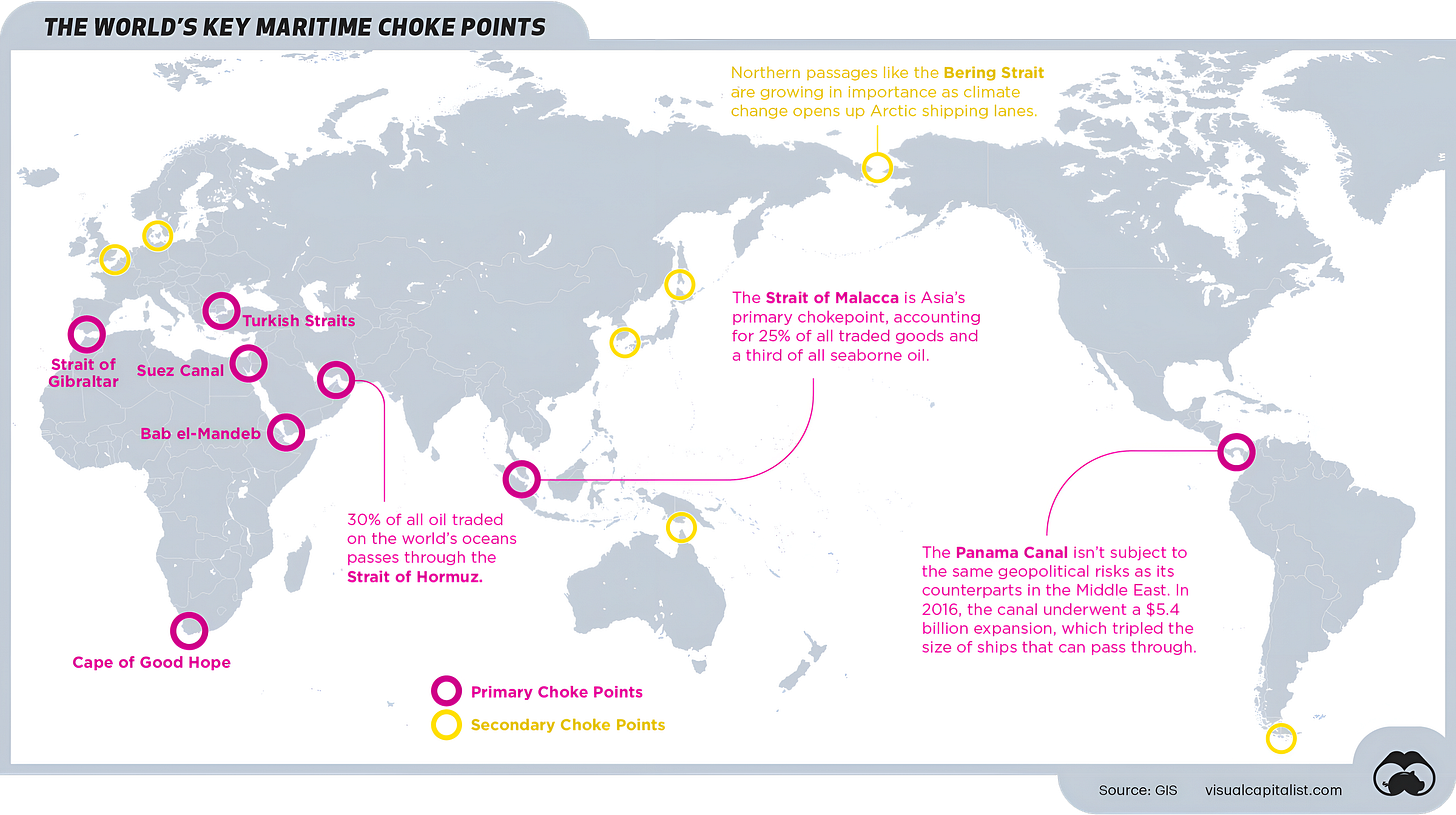

If steel is the backbone and oil is the lifeblood, then shipping routes are the arteries of modern life. As supply chains become more complex, they also become more vulnerable. There are many potential bottlenecks – straits, canals, ports, and bridges – through which goods must routinely pass to reach their destination. But it's our heavy dependence on a few narrow waterways, called "choke points," that makes global trade alarmingly fragile.

Choke points are narrow passages in the world's oceans that connect major shipping routes. In maritime trade, these are typically straits or canals that experience high volumes of traffic due to their strategic locations.

Despite their convenience, these vital points pose several risks:

Structural risks: As demonstrated by the recent Suez Canal blockage, ships can run aground if a passage is too narrow, causing traffic jams that can last for days.

Geopolitical risks: Due to their high traffic volume, choke points are particularly vulnerable to blockades or deliberate disruptions during times of political unrest.

Countries employ various strategies to control these choke points, both to secure their own supplies and to potentially cut off supplies to their adversaries. A few critical chokepoints include:

1. The Strait of Malacca

The Strait of Malacca, situated between Singapore, Malaysia, and Indonesia, is the shortest shipping route connecting East Asia to the Middle East and Europe. It links the South China Sea with the Indian Ocean and handles 40% of the world's trade.

Piracy remains a persistent threat in these waters, with modern-day pirates targeting oil tankers and container ships. Additionally, a collision or environmental disaster could also block this narrow passage. If the Strait of Malacca were to be blocked, ships would need to detour thousands of miles around Australia, delaying the delivery of goods by approximately 10 to 14 days and driving up costs for everything from electronics to crude oil.

This route is particularly crucial for China, as 67% of its trade, including 80% of its energy imports, passes through the strait annually. Concerned about potential disruptions, China launched the Belt and Road Initiative (BRI) to develop alternatives, including pipelines through Myanmar and the proposed Kra Canal in Thailand as potential bypasses.

To project its power in the region, China has expanded its naval presence in the region by increasing its naval bases. In response to which, India strengthened its own naval presence in the Andaman and Nicobar Islands, which are strategically located at the entrance of the Malacca Strait and could potentially control access to this strait.

Due to ongoing disputes between China and several ASEAN members over territorial claims in the South China Sea, coupled with rising U.S.-China tensions, this strategic chokepoint faces significant geopolitical uncertainty.

2. The Strait of Hormuz

This strait, between Iran to the north and UAE and Oman to the south, is significant for both energy and goods shipping.

Some 30% of oil & LNG trade, and a significant amount of global goods shipping volumes passes through this 21-mile-wide passage.

Iran holds strategic control over the strait and has frequently threatened to close it in response to increasing U.S. sanctions. Therefore, U.S. and its allies maintain a strong naval presence to ensure it remains open, making this one of the most militarized choke points.

A blockage here would cause global oil prices to skyrocket, impacting industries, transportation, and heating costs worldwide.

3. The Suez Canal and Bab El-Mandeb Strait

The Suez Canal connects the Mediterranean Sea to the Indian Ocean via the Red Sea and the Gulf of Aden, and normally accounts for about 12% of global maritime trade.

Since its opening in 1869, it has served as a maritime shortcut between the Asian, African and European markets. Asia to Europe, It cuts 7,000 kms off the journey between Asia and Europe. Without this route, ships would need to sail around Africa, which would add a couple of weeks to their trips.

Egypt owns and operates this canal, earning over $6 billion annually from tolls. Rising tensions in the Middle East make the canal a potential flashpoint.

Since the start of Houthi attacks on international shipping in late 2023, some 470 container vessels have already been re-routed. Sending ships around the Cape of Good Hope adds between 9 and 17 days of transit time.

The Bab el-Mandeb Strait is another important shipping route in the region for the world’s oil and natural gas. Nestled between Africa and the Middle East, this region is well known as a high-risk area for pirate attacks.

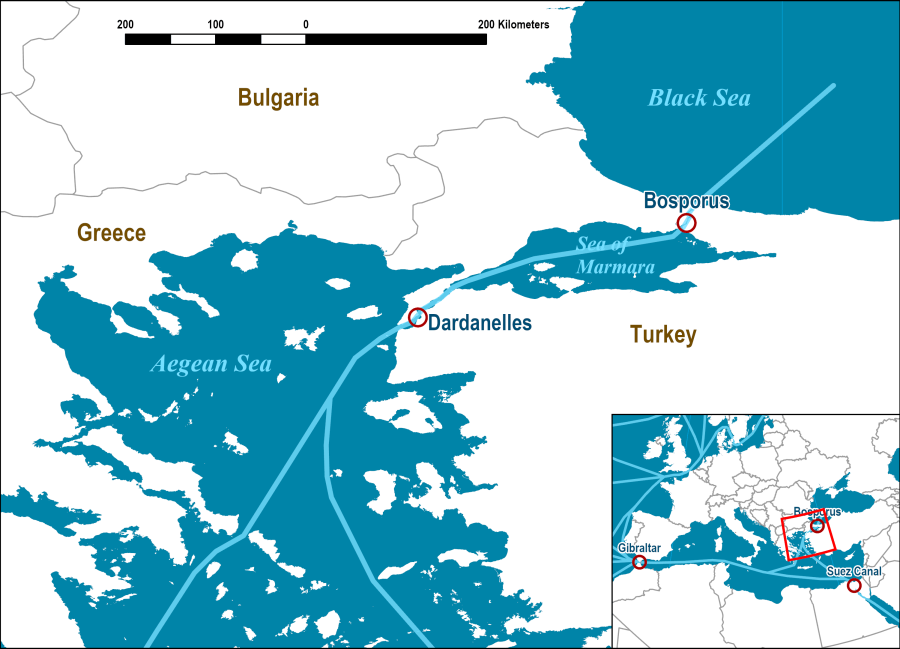

3. The Turkish Straits

The Turkish Strait consists with two main waterways namely, Bosporus and Dardanelles which separate Asia from Europe. The Bosporus Strait links Sea of Marmara to Black Sea, whereas Dardanelles Strait connects Sea of Marmara with the Aegean and Mediterranean Sea.

This is a key route for Russian oil and grain exports. As the straits are narrow and winding, congestion is a constant issue in these waterways. Political disputes, such as Turkey’s strained relations with neighboring countries, add to the risks. Any disruption here would severely affect Russia’s economy and global grain supplies, particularly to Europe and the Middle East.

Turkey controls these straits and plays a delicate balancing act between Russia and NATO. Recent tensions over the Russia-Ukraine war have made this choke point a geopolitical hotspot.

4. The Strait of Gibraltar

The Strait of Gibraltar located between Spain and Morocco narrow waterway which connects Mediterranean Sea and Atlantic Ocean, and handles Europe’s trade with North & Latin America.

The region’s control remains a lingering point of contention. Spain and UK frequently clash over sovereignty, while NATO considers Gibraltar critical for Western security. As this Strait is very deep, its not only vital for commercial purposes, but also military purpose because submarines can operate submerged, throughout the waterway.

Any naval accident or a blockade in this region could delay or severely disrupt shipments of cars, machinery, and agricultural products, hurting European and American economies.

5. The Panama Canal

The canal, which links the Atlantic Ocean and the Pacific Ocean, is vital for U.S.- China trade and global shipments of grain and coal. It accounts for 5% of total global container trade, and some 46% of the trade from the US East Coast to East Asia.

Ships rerouting around South America’s Cape Horn would face an additional 6-day delay and higher costs, affecting the global supply of goods from Latin America and the U.S.

Climate change is the biggest threat in this region as the El Niño weather phenomenon has led to lower water levels in this region. The authority that manages the canal has responded to low water levels by temporarily reducing both the number of transits and reducing the weight of the cargo that can pass through.

This canal is under Panama’s control, but the U.S. has a vested interest in its smooth operation. China is investing heavily in Panamanian infrastructure, seeking to increase its influence over this critical route.

Geopolitical risks could make it downright impossible to move goods to certain places. But here’s the thing—disruptions like these often open the door for innovation. Shipping companies now have a chance to step up, think outside the box, and create smarter, more resilient solutions for the future.

If you have any questions or want to share your thoughts, feel free to reach out in the comments 💬 below.

See you next time!😊

Insightful !